ZheJiang Chengjiu Pipeline Co., Ltd.

Tel: 0086-0570-5012312

Fax: 0086-0570-5012312

E-mail: sales@cheng-jiu.cn

Slip On Flange

- Home

- >

- Flange Size

- >

- Standards

- >

- ANSI (ASME / ASA)...

- >

- Slip On Flange

| |||||

| | | ||||

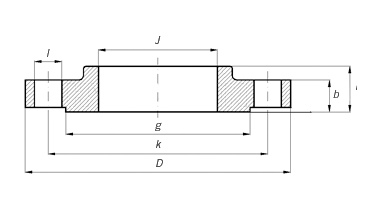

Flange Dimensions & Approximate Masses |

ANSI, ASME, ASA, B16.5 150lb/sq.in. SLIP ON FLANGE RF / FF | ||||||||||

ø | D | b | g | m | J | h | k | Holes | l | Kg. |

1/2" | 88,9 | 11,1 | 34,9 | 30,2 | 22,3 | 15,9 | 60,3 | 4 | 15,9 | 0,400 |

3/4" | 98,4 | 12,7 | 42,9 | 38,1 | 27,7 | 15,9 | 69,8 | 4 | 15,9 | 0,700 |

1" | 107,9 | 14,3 | 50,8 | 49,2 | 34,5 | 17,5 | 79,4 | 4 | 15,9 | 0,800 |

1 1/4" | 117,5 | 15,9 | 63,5 | 58,8 | 43,2 | 20,6 | 88,9 | 4 | 15,9 | 1,100 |

1 1/2" | 127,0 | 17,5 | 73,0 | 65,1 | 49,5 | 22,2 | 98,4 | 4 | 15,9 | 1,400 |

2" | 152,4 | 19,0 | 92,1 | 77,8 | 62,0 | 25,4 | 120,6 | 4 | 19,0 | 2,200 |

2 1/2" | 177,8 | 22,2 | 104,8 | 90,5 | 74,7 | 28,6 | 139,7 | 4 | 19,0 | 3,600 |

3" | 190,5 | 23,8 | 127,0 | 107,9 | 90,7 | 30,2 | 152,4 | 4 | 19,0 | 4,100 |

3 1/2" | 215,9 | 23,8 | 139,7 | 122,2 | 103,4 | 31,7 | 177,8 | 8 | 19,0 | 5,200 |

4" | 228,6 | 23,8 | 157,2 | 134,9 | 116,1 | 33,3 | 190,5 | 8 | 19,0 | 5,600 |

5" | 254,0 | 23,8 | 185,7 | 163,6 | 143,8 | 36,5 | 215,9 | 8 | 22,2 | 6,300 |

6" | 279,4 | 25,4 | 215,9 | 192,1 | 170,7 | 39,7 | 241,3 | 8 | 22,2 | 7,500 |

8" | 342,9 | 28,6 | 269,9 | 246,1 | 221,5 | 44,4 | 298,4 | 8 | 22,2 | 12,600 |

10" | 406,4 | 30,2 | 323,8 | 304,8 | 276,3 | 49,2 | 361,9 | 12 | 25,4 | 18,500 |

12" | 482,6 | 31,7 | 381,0 | 365,1 | 327,1 | 55,6 | 431,8 | 12 | 25,5 | 28,000 |

14" | 533,4 | 34,9 | 412,7 | 400,0 | 359,1 | 57,1 | 476,2 | 12 | 28,6 | 36,000 |

16" | 596,9 | 36,5 | 469,9 | 457,2 | 410,5 | 63,5 | 539,7 | 16 | 28,6 | 46,000 |

18" | 635,0 | 39,7 | 533,4 | 504,8 | 461,8 | 68,3 | 577,8 | 16 | 31,7 | 50,000 |

20" | 698,5 | 42,9 | 584,2 | 558,8 | 513,1 | 73,0 | 635,0 | 20 | 31,7 | 64,000 |

22" | 749,3 | 46,0 | 641,2 | 609,6 | 564,4 | 79,4 | 692,1 | 20 | 34,9 | 72,000 |

24" | 812,8 | 47,6 | 692,1 | 663,6 | 615,9 | 82,5 | 749,3 | 20 | 34,9 | 89,000 |

NOTE: |

ANSI, ASME, ASA, B16.5 300lb/sq.in. SLIP ON FLANGE RF / FF | ||||||||||

ø | D | b | g | m | J | h | k | Holes | l | Kg. |

1/2" | 95,6 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,700 |

3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,100 |

1" | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,400 |

1 1/4" | 133,3 | 19,0 | 63,5 | 63,5 | 43,2 | 27,0 | 98,4 | 4 | 19,0 | 1,800 |

1 1/2" | 155,6 | 20,6 | 73,0 | 69,8 | 49,5 | 30,2 | 114,3 | 4 | 22,2 | 2,600 |

2" | 165,1 | 22,2 | 92,1 | 84,1 | 62,0 | 33,3 | 127,0 | 8 | 19,0 | 3,400 |

2 1/2" | 190,5 | 25,4 | 104,8 | 100,0 | 74,7 | 38,1 | 149,2 | 8 | 22,2 | 4,400 |

3" | 209,5 | 28,6 | 127,0 | 117,5 | 90,7 | 42,9 | 168,3 | 8 | 22,2 | 6,100 |

3 1/2" | 228,6 | 30,2 | 139,7 | 133,3 | 103,4 | 44,4 | 184,1 | 8 | 22,2 | 7,500 |

4" | 254,0 | 31,7 | 157,2 | 146,0 | 116,1 | 47,6 | 200,0 | 8 | 22,2 | 10,100 |

5" | 279,4 | 34,9 | 185,7 | 177,8 | 143,8 | 50,8 | 234,9 | 8 | 22,2 | 12,500 |

6" | 317,5 | 36,5 | 215,9 | 206,4 | 170,7 | 52,4 | 269,9 | 12 | 22,2 | 14,100 |

8" | 381,0 | 41,3 | 269,9 | 260,3 | 221,5 | 61,9 | 330,2 | 12 | 25,4 | 24,800 |

10" | 444,5 | 47,6 | 323,8 | 320,7 | 276,3 | 66,7 | 387,3 | 16 | 28,6 | 37,100 |

12" | 520,7 | 50,8 | 381,0 | 374,6 | 327,1 | 73,0 | 450,8 | 16 | 31,7 | 50,000 |

14" | 584,2 | 54,0 | 412,7 | 425,4 | 359,1 | 76,2 | 514,3 | 20 | 31,7 | 70,000 |

16" | 647,7 | 57,1 | 469,9 | 482,6 | 410,5 | 82,5 | 571,5 | 20 | 34,9 | 90,000 |

18" | 711,2 | 60,3 | 533,4 | 533,4 | 461,8 | 88,9 | 628,6 | 24 | 34,9 | 112,000 |

20" | 774,7 | 63,5 | 584,2 | 584,2 | 513,1 | 95,2 | 685,8 | 24 | 34,9 | 133,000 |

22" | 838,2 | 66,7 | 641,2 | 641,2 | 564,4 | 101,6 | 742,9 | 24 | 41,3 | 197,000 |

24" | 914,4 | 69,8 | 692,1 | 701,7 | 615,9 | 106,4 | 812,8 | 24 | 41,3 | 208,000 |

NOTE: |

ANSI, ASME, ASA, B16.5 600lb/sq.in. Flange SLIP ON FLANGE RF/ FF | ||||||||||

ø | D | b | g | m | J | h | k | Holes | l | Kg. |

1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,800 |

3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,400 |

1" | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,600 |

1 1/4" | 133,3 | 20,6 | 63,5 | 63,5 | 43,2 | 28,6 | 98,4 | 4 | 19,0 | 2,100 |

1 1/2" | 155,6 | 22,2 | 73,0 | 69,8 | 49,5 | 31,7 | 114,3 | 4 | 22,2 | 3,100 |

2" | 165,1 | 25,4 | 92,1 | 84,1 | 62,0 | 36,5 | 127,0 | 8 | 19,0 | 3,700 |

2 1/2" | 190,5 | 28,6 | 104,8 | 100,0 | 74,7 | 41,3 | 149,2 | 8 | 22,2 | 5,400 |

3" | 209,5 | 31,7 | 127,0 | 117,5 | 90,7 | 46,0 | 168,3 | 8 | 22,2 | 7,300 |

3 1/2" | 228,6 | 34,9 | 139,7 | 133,3 | 103,4 | 49,2 | 184,1 | 8 | 25,4 | 8,900 |

4" | 273,0 | 38,1 | 157,2 | 152,4 | 116,1 | 54,0 | 215,9 | 8 | 25,4 | 11,800 |

5" | 330,2 | 44,4 | 185,7 | 188,9 | 143,8 | 60,3 | 266,7 | 8 | 28,6 | 24,500 |

6" | 355,6 | 47,6 | 215,9 | 222,2 | 170,7 | 66,7 | 292,1 | 12 | 28,6 | 29,500 |

8" | 419,1 | 55,6 | 269,9 | 273,0 | 221,5 | 76,2 | 349,2 | 12 | 31,7 | 43,000 |

10" | 508,0 | 63,5 | 323,8 | 342,8 | 276,3 | 85,7 | 431,8 | 16 | 34,9 | 70,000 |

12" | 558,8 | 66,7 | 381,0 | 400,0 | 327,1 | 92,1 | 488,9 | 20 | 34,9 | 86,000 |

14" | 603,2 | 69,8 | 412,7 | 431,8 | 359,1 | 93,7 | 527,0 | 20 | 38,1 | 100,000 |

16" | 685,8 | 76,2 | 469,9 | 495,3 | 410,5 | 106,4 | 603,2 | 20 | 41,3 | 142,000 |

18" | 742,9 | 82,5 | 533,4 | 546,1 | 461,8 | 117,5 | 654,0 | 20 | 44,4 | 175,000 |

20" | 812,8 | 88,9 | 584,2 | 609,6 | 513,1 | 127,0 | 723,9 | 24 | 44,4 | 232,000 |

22" | 869,9 | 95,2 | 641,2 | 666,7 | 564,4 | 133,3 | 777,9 | 24 | 47,6 | 292,000 |

24" | 939,8 | 101,6 | 692,1 | 717,5 | 615,9 | 139,7 | 838,2 | 24 | 50,8 | 330,000 |

NOTE: |

| |

Production Capacity & Purchase Details | |

|

|

1. | Supply Flange Dimension DN15 - DN2000 (1/2" - 80"), Forged Flange. |

2. | Material Carbon Steel: ASTM A105, A181, A350 LF1, A350LF2, A350LF3, A36, A234 WPB, Q235B, 20#, 20Mn etc. |

3. | Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc. |

4. | Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc. |

5. | Monthly Output: 3000 tons per Month. |

6. | Delivery Terms: CIF, CFR, FOB, EXW. |

7. | Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight etc. |

8. | Minimum Order Quantity: 1Ton or 100Pcs. |

9. | Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service. |

10. | Find More Requirements In Flanges Market. |

ZheJiang Chengjiu Pipeline Co., Ltd.

Tel: 0086-0570-5012312

Fax: 0086-0570-5012312

E-mail: sales@cheng-jiu.cn

Slip On Flange

- Home

- >

- Flange Size

- >

- Standards

- >

- ANSI (ASME / ASA)...

- >

- Slip On Flange

| |||||

| | | ||||

Flange Dimensions & Approximate Masses |

ANSI, ASME, ASA, B16.5 150lb/sq.in. SLIP ON FLANGE RF / FF | ||||||||||

ø | D | b | g | m | J | h | k | Holes | l | Kg. |

1/2" | 88,9 | 11,1 | 34,9 | 30,2 | 22,3 | 15,9 | 60,3 | 4 | 15,9 | 0,400 |

3/4" | 98,4 | 12,7 | 42,9 | 38,1 | 27,7 | 15,9 | 69,8 | 4 | 15,9 | 0,700 |

1" | 107,9 | 14,3 | 50,8 | 49,2 | 34,5 | 17,5 | 79,4 | 4 | 15,9 | 0,800 |

1 1/4" | 117,5 | 15,9 | 63,5 | 58,8 | 43,2 | 20,6 | 88,9 | 4 | 15,9 | 1,100 |

1 1/2" | 127,0 | 17,5 | 73,0 | 65,1 | 49,5 | 22,2 | 98,4 | 4 | 15,9 | 1,400 |

2" | 152,4 | 19,0 | 92,1 | 77,8 | 62,0 | 25,4 | 120,6 | 4 | 19,0 | 2,200 |

2 1/2" | 177,8 | 22,2 | 104,8 | 90,5 | 74,7 | 28,6 | 139,7 | 4 | 19,0 | 3,600 |

3" | 190,5 | 23,8 | 127,0 | 107,9 | 90,7 | 30,2 | 152,4 | 4 | 19,0 | 4,100 |

3 1/2" | 215,9 | 23,8 | 139,7 | 122,2 | 103,4 | 31,7 | 177,8 | 8 | 19,0 | 5,200 |

4" | 228,6 | 23,8 | 157,2 | 134,9 | 116,1 | 33,3 | 190,5 | 8 | 19,0 | 5,600 |

5" | 254,0 | 23,8 | 185,7 | 163,6 | 143,8 | 36,5 | 215,9 | 8 | 22,2 | 6,300 |

6" | 279,4 | 25,4 | 215,9 | 192,1 | 170,7 | 39,7 | 241,3 | 8 | 22,2 | 7,500 |

8" | 342,9 | 28,6 | 269,9 | 246,1 | 221,5 | 44,4 | 298,4 | 8 | 22,2 | 12,600 |

10" | 406,4 | 30,2 | 323,8 | 304,8 | 276,3 | 49,2 | 361,9 | 12 | 25,4 | 18,500 |

12" | 482,6 | 31,7 | 381,0 | 365,1 | 327,1 | 55,6 | 431,8 | 12 | 25,5 | 28,000 |

14" | 533,4 | 34,9 | 412,7 | 400,0 | 359,1 | 57,1 | 476,2 | 12 | 28,6 | 36,000 |

16" | 596,9 | 36,5 | 469,9 | 457,2 | 410,5 | 63,5 | 539,7 | 16 | 28,6 | 46,000 |

18" | 635,0 | 39,7 | 533,4 | 504,8 | 461,8 | 68,3 | 577,8 | 16 | 31,7 | 50,000 |

20" | 698,5 | 42,9 | 584,2 | 558,8 | 513,1 | 73,0 | 635,0 | 20 | 31,7 | 64,000 |

22" | 749,3 | 46,0 | 641,2 | 609,6 | 564,4 | 79,4 | 692,1 | 20 | 34,9 | 72,000 |

24" | 812,8 | 47,6 | 692,1 | 663,6 | 615,9 | 82,5 | 749,3 | 20 | 34,9 | 89,000 |

NOTE: |

ANSI, ASME, ASA, B16.5 300lb/sq.in. SLIP ON FLANGE RF / FF | ||||||||||

ø | D | b | g | m | J | h | k | Holes | l | Kg. |

1/2" | 95,6 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,700 |

3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,100 |

1" | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,400 |

1 1/4" | 133,3 | 19,0 | 63,5 | 63,5 | 43,2 | 27,0 | 98,4 | 4 | 19,0 | 1,800 |

1 1/2" | 155,6 | 20,6 | 73,0 | 69,8 | 49,5 | 30,2 | 114,3 | 4 | 22,2 | 2,600 |

2" | 165,1 | 22,2 | 92,1 | 84,1 | 62,0 | 33,3 | 127,0 | 8 | 19,0 | 3,400 |

2 1/2" | 190,5 | 25,4 | 104,8 | 100,0 | 74,7 | 38,1 | 149,2 | 8 | 22,2 | 4,400 |

3" | 209,5 | 28,6 | 127,0 | 117,5 | 90,7 | 42,9 | 168,3 | 8 | 22,2 | 6,100 |

3 1/2" | 228,6 | 30,2 | 139,7 | 133,3 | 103,4 | 44,4 | 184,1 | 8 | 22,2 | 7,500 |

4" | 254,0 | 31,7 | 157,2 | 146,0 | 116,1 | 47,6 | 200,0 | 8 | 22,2 | 10,100 |

5" | 279,4 | 34,9 | 185,7 | 177,8 | 143,8 | 50,8 | 234,9 | 8 | 22,2 | 12,500 |

6" | 317,5 | 36,5 | 215,9 | 206,4 | 170,7 | 52,4 | 269,9 | 12 | 22,2 | 14,100 |

8" | 381,0 | 41,3 | 269,9 | 260,3 | 221,5 | 61,9 | 330,2 | 12 | 25,4 | 24,800 |

10" | 444,5 | 47,6 | 323,8 | 320,7 | 276,3 | 66,7 | 387,3 | 16 | 28,6 | 37,100 |

12" | 520,7 | 50,8 | 381,0 | 374,6 | 327,1 | 73,0 | 450,8 | 16 | 31,7 | 50,000 |

14" | 584,2 | 54,0 | 412,7 | 425,4 | 359,1 | 76,2 | 514,3 | 20 | 31,7 | 70,000 |

16" | 647,7 | 57,1 | 469,9 | 482,6 | 410,5 | 82,5 | 571,5 | 20 | 34,9 | 90,000 |

18" | 711,2 | 60,3 | 533,4 | 533,4 | 461,8 | 88,9 | 628,6 | 24 | 34,9 | 112,000 |

20" | 774,7 | 63,5 | 584,2 | 584,2 | 513,1 | 95,2 | 685,8 | 24 | 34,9 | 133,000 |

22" | 838,2 | 66,7 | 641,2 | 641,2 | 564,4 | 101,6 | 742,9 | 24 | 41,3 | 197,000 |

24" | 914,4 | 69,8 | 692,1 | 701,7 | 615,9 | 106,4 | 812,8 | 24 | 41,3 | 208,000 |

NOTE: |

ANSI, ASME, ASA, B16.5 600lb/sq.in. Flange SLIP ON FLANGE RF/ FF | ||||||||||

ø | D | b | g | m | J | h | k | Holes | l | Kg. |

1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,800 |

3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,400 |

1" | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,600 |

1 1/4" | 133,3 | 20,6 | 63,5 | 63,5 | 43,2 | 28,6 | 98,4 | 4 | 19,0 | 2,100 |

1 1/2" | 155,6 | 22,2 | 73,0 | 69,8 | 49,5 | 31,7 | 114,3 | 4 | 22,2 | 3,100 |

2" | 165,1 | 25,4 | 92,1 | 84,1 | 62,0 | 36,5 | 127,0 | 8 | 19,0 | 3,700 |

2 1/2" | 190,5 | 28,6 | 104,8 | 100,0 | 74,7 | 41,3 | 149,2 | 8 | 22,2 | 5,400 |

3" | 209,5 | 31,7 | 127,0 | 117,5 | 90,7 | 46,0 | 168,3 | 8 | 22,2 | 7,300 |

3 1/2" | 228,6 | 34,9 | 139,7 | 133,3 | 103,4 | 49,2 | 184,1 | 8 | 25,4 | 8,900 |

4" | 273,0 | 38,1 | 157,2 | 152,4 | 116,1 | 54,0 | 215,9 | 8 | 25,4 | 11,800 |

5" | 330,2 | 44,4 | 185,7 | 188,9 | 143,8 | 60,3 | 266,7 | 8 | 28,6 | 24,500 |

6" | 355,6 | 47,6 | 215,9 | 222,2 | 170,7 | 66,7 | 292,1 | 12 | 28,6 | 29,500 |

8" | 419,1 | 55,6 | 269,9 | 273,0 | 221,5 | 76,2 | 349,2 | 12 | 31,7 | 43,000 |

10" | 508,0 | 63,5 | 323,8 | 342,8 | 276,3 | 85,7 | 431,8 | 16 | 34,9 | 70,000 |

12" | 558,8 | 66,7 | 381,0 | 400,0 | 327,1 | 92,1 | 488,9 | 20 | 34,9 | 86,000 |

14" | 603,2 | 69,8 | 412,7 | 431,8 | 359,1 | 93,7 | 527,0 | 20 | 38,1 | 100,000 |

16" | 685,8 | 76,2 | 469,9 | 495,3 | 410,5 | 106,4 | 603,2 | 20 | 41,3 | 142,000 |

18" | 742,9 | 82,5 | 533,4 | 546,1 | 461,8 | 117,5 | 654,0 | 20 | 44,4 | 175,000 |

20" | 812,8 | 88,9 | 584,2 | 609,6 | 513,1 | 127,0 | 723,9 | 24 | 44,4 | 232,000 |

22" | 869,9 | 95,2 | 641,2 | 666,7 | 564,4 | 133,3 | 777,9 | 24 | 47,6 | 292,000 |

24" | 939,8 | 101,6 | 692,1 | 717,5 | 615,9 | 139,7 | 838,2 | 24 | 50,8 | 330,000 |

NOTE: |

| |

Production Capacity & Purchase Details | |

|

|

1. | Supply Flange Dimension DN15 - DN2000 (1/2" - 80"), Forged Flange. |

2. | Material Carbon Steel: ASTM A105, A181, A350 LF1, A350LF2, A350LF3, A36, A234 WPB, Q235B, 20#, 20Mn etc. |

3. | Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc. |

4. | Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc. |

5. | Monthly Output: 3000 tons per Month. |

6. | Delivery Terms: CIF, CFR, FOB, EXW. |

7. | Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight etc. |

8. | Minimum Order Quantity: 1Ton or 100Pcs. |

9. | Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service. |

10. | Find More Requirements In Flanges Market. |