ANSI, ASME, ASA, B16.5 THREADED SCREWED FLANGE | | CLASS 150 / 300 / 600 | |

|  |  |

Flange Dimensions & Approximate Masses |

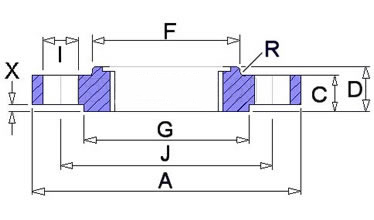

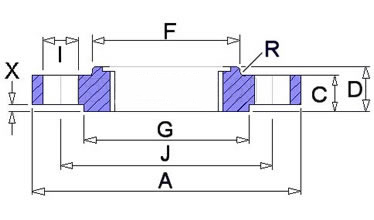

ANSI, ASME, ASA, B16.5 150lb/sq.in. Threaded Flange NPT | Pipe | Flange Data | Hub Data | Raised Face | Drilling Data | Weight | Nominal Size | | A | C | D | E | F | G | H | I | J | | Outside Dia | Overall Dia | Flange Thickness min | Overall Length | Threaded Length min | Hub Dia | Face Dia | Number of Holes | Bolt Hole Dia | Dia of Circle of Holes | Kg/ Piece | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | ½ | 0.84 | 3.50 | 0.440 | 0.620 | 0.620 | 1.190 | 1.38 | 4 | 0.62 | 2.38 | 0.39 | | 21.3 | 88.90 | 11.20 | 15.70 | 15.70 | 30.20 | 35.10 | | 15.7 | 60.45 | | ¾ | 1.05 | 3.88 | 0.500 | 0.620 | 0.620 | 1.500 | 1.69 | 4 | 0.62 | 2.75 | 0.56 | | 26.7 | 98.60 | 12.70 | 15.70 | 15.70 | 38.10 | 42.9 | | 15.7 | 69.85 | | 1 | 1.315 | 4.25 | 0.560 | 0.690 | 0.690 | 1.940 | 2 | 4 | 0.62 | 3.12 | 0.78 | | 33.4 | 108.00 | 14.20 | 17.50 | 17.50 | 49.30 | 50.8 | | 15.7 | 79.25 | | 1 ¼ | 1.66 | 4.62 | 0.620 | 0.810 | 0.810 | 2.310 | 2.5 | 4 | 0.62 | 3.50 | 1.03 | | 42.2 | 117.30 | 15.70 | 20.60 | 20.60 | 58.70 | 63.5 | | 15.7 | 88.90 | | 1 ½ | 1.9 | 5.00 | 0.690 | 0.880 | 0.880 | 2.560 | 2.88 | 4 | 0.62 | 3.88 | 1.32 | | 48.3 | 127.00 | 17.50 | 22.40 | 22.40 | 65.00 | 73.15 | | 15.7 | 98.60 | | 2 | 2.375 | 6.00 | 0.750 | 1.000 | 1.000 | 3.060 | 3.62 | 4 | 0.75 | 4.75 | 2.06 | | 60.3 | 152.40 | 19.10 | 25.40 | 25.40 | 77.70 | 91.9 | | 19.10 | 120.70 | | 2 ½ | 2.875 | 7.00 | 0.880 | 1.120 | 1.120 | 3.560 | 4.12 | 4 | 0.75 | 5.50 | 3.28 | | 73 | 177.80 | 22.40 | 28.40 | 28.40 | 90.40 | 104.6 | | 19.10 | 139.70 | | 3 | 3.5 | 7.50 | 0.940 | 1.190 | 1.190 | 4.250 | 5 | 4 | 0.75 | 6.00 | 3.85 | | 88.9 | 190.50 | 23.90 | 30.20 | 30.20 | 108.00 | 127 | | 19.10 | 152.40 | | 3 ½ | 4 | 8.50 | 0.940 | 1.250 | 1.250 | 4.810 | 5.5 | 8 | 0.75 | 7.00 | 4.81 | | 101.6 | 215.90 | 23.90 | 31.75 | 31.75 | 122.20 | 139.7 | | 19.10 | 177.80 | | 4 | 4.5 | 9.00 | 0.940 | 1.310 | 1.310 | 5.310 | 6.19 | 8 | 0.75 | 7.50 | 5.30 | | 114.3 | 228.60 | 23.90 | 33.30 | 33.30 | 134.90 | 157.2 | | 19.10 | 190.50 | | 5 | 5.563 | 10.00 | 0.940 | 1.440 | 1.440 | 6.440 | 7.31 | 8 | 0.88 | 8.50 | 6.07 | | 141.3 | 254.00 | 23.90 | 36.60 | 36.60 | 163.60 | 185.7 | | 22.40 | 215.90 | | 6 | 6.625 | 11.00 | 1.000 | 1.560 | 1.560 | 7.560 | 8.5 | 8 | 0.88 | 9.50 | 7.45 | | 168.3 | 279.40 | 25.40 | 39.60 | 39.60 | 192.00 | 215.9 | | 22.40 | 241.30 | | 8 | 8.625 | 13.50 | 1.120 | 1.750 | 1.750 | 9.690 | 10.62 | 8 | 0.88 | 11.75 | 12.10 | | 219.1 | 342.90 | 28.40 | 44.50 | 44.50 | 246.10 | 269.7 | | 22.40 | 298.50 | | 10 | 10.75 | 16.00 | 1.190 | 1.940 | 1.940 | 12.00 | 12.75 | 12 | 1.00 | 14.25 | 16.50 | | 273 | 406.40 | 30.20 | 49.30 | 49.30 | 304.80 | 323.8 | | 25.40 | 362.00 | | 12 | 12.75 | 19.00 | 1.250 | 2.190 | 2.190 | 14.380 | 15 | 12 | 1.00 | 17.00 | 26.20 | | 323.8 | 482.60 | 31.75 | 55.60 | 55.60 | 365.30 | 381 | | 25.40 | 431.80 | | 14 | 14 | 21.00 | 1.380 | 2.250 | 2.250 | 15.750 | 16.25 | 12 | 1.12 | 18.75 | 34.60 | | 355.6 | 533.40 | 35.10 | 57.15 | 57.15 | 400.10 | 412.7 | | 28.40 | 476.30 | | 16 | 16 | 23.50 | 1.440 | 2.500 | 2.500 | 18.00 | 18.5 | 16 | 1.12 | 21.25 | 44.80 | | 406.4 | 596.90 | 36.60 | 63.50 | 63.50 | 457.20 | 469.9 | | 28.40 | 539.80 | | 18 | 18 | 25.00 | 1.560 | 2.690 | 2.690 | 19.880 | 21 | 16 | 1.25 | 22.75 | 48.90 | | 457.2 | 635.00 | 39.60 | 68.30 | 68.30 | 505.00 | 533.4 | | 31.75 | 577.90 | | 20 | 20 | 27.50 | 1.690 | 2.880 | 2.880 | 22.00 | 23 | 20 | 1.25 | 25.00 | 61.90 | | 508 | 698.50 | 42.90 | 73.15 | 73.15 | 558.80 | 584.2 | | 31.75 | 635.00 | | 24 | 24 | 32.00 | 1.880 | 3.250 | 3.250 | 26.120 | 27.25 | 20 | 1.38 | 29.50 | 86.90 | | 609.6 | 812.80 | 47.80 | 82.60 | 82.60 | 663.40 | 692.1 | | 35.10 | 749.30 | |

NOTE: 1. The thread conforms to ASME B1.20.1 NTP threads as described in Section 10. (The only exceptions are small male and female plain face threaded flanges which use NPSL recount threads.)

2. Class 150 threaded flanges are made without a counterbore. Threads are chamfered to the major diameter (approx.) at an angle of 45° (approx.) at the back of the flange.

3. Weights are based on manufacturer's data and are approximate.

4. For tolerances +-0.5mm. |

ANSI, ASME, ASA, B16.5 300lb/sq.in. Threaded Flange NPT | Pipe | Flange Data | Hub Data | Raised Face | Drilling Data | Weight | Nominal Size | | A | B | C | D | E | F | G | H | I | J | | Outside Dia | Overall Dia | Counter Bore | Flange Thickness min | Overall Length | Threaded Length min | Hub Dia | Face Dia | Number of Holes | Bolt Hole Dia | Dia of Circle of Holes | Kg/ Piece | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | ½ | 0.84 | 3.75 | 0.93 | 0.56 | 0.88 | 0.62 | 1.5 | 1.38 | 4 | 0.62 | 2.62 | 0.64 | | 21.3 | 95.3 | 23.6 | 14.2 | 22.3 | 15.7 | 38.1 | 35 | | 15.7 | 66.55 | | ¾ | 1.05 | 4.62 | 1.14 | 0.62 | 1 | 0.62 | 1.88 | 1.69 | 4 | 0.75 | 3.25 | 1.12 | | 26.7 | 117.3 | 29 | 15.7 | 25.4 | 15.7 | 42.7 | 42.9 | | 19 | 82.5 | | 1 | 1.315 | 4.88 | 1.41 | 0.69 | 1.06 | 0.69 | 2.12 | 2 | 4 | 0.75 | 3.5 | 1.36 | | 33.4 | 124 | 35.8 | 17.5 | 26.9 | 17.5 | 53.8 | 50.8 | | 19 | 88.9 | | 1 ¼ | 1.66 | 5.25 | 1.75 | 0.75 | 1.06 | 0.81 | 2.5 | 2.5 | 4 | 0.75 | 3.88 | 1.68 | | 42.2 | 133.4 | 44.4 | 19 | 26.9 | 20.6 | 63.5 | 63.5 | | 19 | 98.5 | | 1 ½ | 1.9 | 6.12 | 1.99 | 0.81 | 1.19 | 0.88 | 2.75 | 2.88 | 4 | 0.88 | 4.5 | 2.49 | | 48.3 | 155.4 | 50.5 | 20.6 | 30.2 | 22.3 | 69.85 | 73.15 | | 22.3 | 114.3 | | 2 | 2.375 | 6.5 | 2.5 | 0.88 | 1.31 | 1.12 | 3.31 | 3.62 | 8 | 0.75 | 5 | 2.87 | | 60.3 | 165.1 | 63.5 | 22.3 | 33.2 | 28.4 | 84 | 91.9 | | 19 | 127 | | 2 ½ | 2.875 | 7.5 | 3 | 1 | 1.5 | 1.25 | 3.94 | 4.12 | 8 | 0.88 | 5.88 | 4.32 | | 73 | 190.5 | 76.2 | 25.4 | 38.1 | 31.7 | 100 | 104.6 | | 22.3 | 149.3 | | 3 | 3.5 | 8.25 | 3.63 | 1.12 | 1.69 | 1.25 | 4.62 | 5 | 8 | 0.88 | 6.62 | 5.85 | | 88.9 | 209.6 | 92.2 | 28.4 | 42.9 | 31.7 | 117.3 | 127 | | 22.3 | 168.1 | | 3 ½ | 4 | 9 | 4.13 | 1.19 | 1.75 | 1.44 | 5.25 | 5.5 | 8 | 0.88 | 7.25 | 7.34 | | 101.6 | 228.6 | 104.9 | 30.2 | 44.4 | 36.5 | 133.3 | 139.7 | | 22.3 | 184.1 | | 4 | 4.5 | 10 | 4.63 | 1.25 | 1.88 | 1.44 | 5.75 | 6.19 | 8 | 0.88 | 7.88 | 9.61 | | 114.3 | 254 | 117.6 | 31.7 | 47.7 | 36.5 | 146 | 157.2 | | 22.3 | 200.1 | | 5 | 5.563 | 11 | 5.69 | 1.38 | 2 | 1.69 | 7 | 7.31 | 8 | 0.88 | 9.25 | 12.3 | | 141.3 | 279.4 | 144.5 | 35 | 50.8 | 42.9 | 177.8 | 185.7 | | 22.3 | 234.9 | | 6 | 6.625 | 12.5 | 6.75 | 1.44 | 2.06 | 1.81 | 8.12 | 8.5 | 12 | 0.88 | 10.62 | 15.6 | | 168.3 | 317.5 | 171.4 | 36.5 | 52.3 | 45.9 | 206.2 | 215.9 | | 22.3 | 269.7 | | 8 | 8.625 | 15 | 8.75 | 1.62 | 2.44 | 2 | 10.25 | 10.62 | 12 | 1 | 13 | 24.2 | | 219.1 | 381 | 222.3 | 41.1 | 61.9 | 50.8 | 260.3 | 269.7 | | 25.4 | 330.2 | | 10 | 10.75 | 17.5 | 10.88 | 1.88 | 2.62 | 2.19 | 12.62 | 12.75 | 16 | 1.12 | 15.25 | 34.1 | | 273 | 444.5 | 276.3 | 47.7 | 66.55 | 55.6 | 320.5 | 323.8 | | 28.4 | 387.3 | | 12 | 12.75 | 20.5 | 12.94 | 2 | 2.88 | 2.38 | 14.75 | 15 | 16 | 1.25 | 17.75 | 49.8 | | 323.8 | 520.7 | 328.7 | 50.8 | 73.15 | 60.45 | 374.6 | 381 | | 31.7 | 450.8 | | 14 | 14 | 23 | 14.19 | 2.12 | 3 | 2.5 | 16.75 | 16.25 | 20 | 1.25 | 20.25 | 69.9 | | 355.6 | 584.2 | 360.4 | 53.8 | 76.2 | 63.5 | 425.4 | 412.7 | | 31.7 | 514.3 | | 16 | 16 | 25.5 | 16.19 | 2.25 | 3.25 | 2.69 | 19 | 18.5 | 20 | 1.38 | 22.5 | 88.1 | | 406.4 | 647.7 | 411.2 | 57.15 | 82.5 | 68.3 | 482.6 | 469.9 | | 35 | 571.5 | | 18 | 18 | 28 | 18.19 | 2.38 | 3.5 | 2.75 | 21 | 21 | 24 | 1.38 | 24.75 | 109 | | 457.2 | 711.2 | 462 | 60.45 | 88.9 | 69.85 | 533.4 | 533.4 | | 35 | 628.6 | | 20 | 20 | 30.5 | 20.19 | 2.5 | 3.75 | 2.88 | 23.12 | 23 | 24 | 1.38 | 27 | 134 | | 508 | 774.7 | 512.8 | 63.5 | 95.2 | 73.15 | 587.2 | 584.2 | | 35 | 685.8 | | 24 | 24 | 36 | 24.19 | 2.75 | 4.19 | 3.25 | 27.62 | 27.25 | 24 | 1.62 | 32 | 201 | | 609.6 | 914.4 | 614.4 | 69.85 | 106.4 | 82.5 | 701.5 | 692.1 | | 41.1 | 812.8 | |

NOTE: 1. Class 300 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option. |

ANSI, ASME, ASA, B16.5 600lb/sq.in. Threaded Flange NPT | Pipe | Flange Data | Hub Data | Raised Face | Drilling Data | Weight | Nominal Size | | A | B | C | D | E | F | G | H | I | J | | Outside Dia | Overall Dia | Counter Bore | Flange Thickness min | Overall Length | Threaded Length min | Hub Dia | Face Dia | Number of Holes | Bolt Hole Dia | Dia of Circle of Holes | Kg/ Piece | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | In Mm | ½ | 0.84 | 3.75 | 0.93 | 0.56 | 0.88 | 0.62 | 1.5 | 1.38 | 4 | 0.62 | 2.62 | 0.74 | | 21.3 | 95.3 | 23.6 | 14.2 | 22.4 | 15.7 | 38.1 | 35 | | 15.7 | 66.55 | | ¾ | 1.05 | 4.62 | 1.14 | 0.62 | 1 | 0.62 | 1.88 | 1.69 | 4 | 0.75 | 3.25 | 1.27 | | 26.7 | 117.3 | 29 | 15.7 | 25.4 | 15.7 | 47.8 | 42.9 | | 19.1 | 82.6 | | 1 | 1.315 | 4.88 | 1.41 | 0.69 | 1.12 | 0.69 | 2.12 | 2 | 4 | 0.75 | 3.5 | 1.52 | | 33.4 | 124 | 35.8 | 17.5 | 28.4 | 17.5 | 53.8 | 50.8 | | 19.1 | 88.9 | | 1 ¼ | 1.66 | 5.25 | 1.75 | 0.81 | 1.12 | 0.81 | 2.5 | 2.5 | 4 | 0.75 | 3.88 | 2.03 | | 42.2 | 133.4 | 44.4 | 20.6 | 28.4 | 20.6 | 63.5 | 63.5 | | 19.1 | 98.6 | | 1 ½ | 1.9 | 6.12 | 1.99 | 0.88 | 1.25 | 0.88 | 2.75 | 2.88 | 4 | 0.88 | 4.5 | 2.96 | | 48.3 | 155.4 | 50.5 | 22.4 | 31.75 | 22.4 | 69.85 | 73.15 | | 22.4 | 114.3 | | 2 | 2.375 | 6.5 | 2.5 | 1 | 1.44 | 1.12 | 3.31 | 3.62 | 8 | 0.75 | 5 | 3.62 | | 60.3 | 165.1 | 63.5 | 25.4 | 36.6 | 28.4 | 84.1 | 91.9 | | 19.1 | 127 | | 2 ½ | 2.875 | 7.5 | 3 | 1.12 | 1.62 | 1.25 | 3.94 | 4.12 | 8 | 0.88 | 5.88 | 5.28 | | 73 | 190.5 | 76.2 | 28.4 | 41.1 | 31.75 | 100.1 | 104.6 | | 22.4 | 149.4 | | 3 | 3.5 | 8.25 | 3.63 | 1.25 | 1.81 | 1.38 | 4.62 | 5 | 8 | 0.88 | 6.62 | 7 | | 88.9 | 209.6 | 92.2 | 31.75 | 46 | 35.1 | 117.3 | 127 | | 22.4 | 168.1 | | 3 ½ | 4 | 9 | 4.13 | 1.38 | 1.94 | 1.56 | 5.25 | 5.5 | 8 | 1 | 7.25 | 8.84 | | 101.6 | 228.6 | 104.9 | 35.1 | 49.3 | 39.6 | 133.4 | 139.7 | | 25.4 | 184.2 | | 4 | 4.5 | 10.75 | 4.63 | 1.5 | 2.12 | 1.62 | 6 | 6.19 | 8 | 1 | 8.5 | 14.5 | | 114.3 | 273.1 | 117.6 | 38.1 | 53.8 | 41.1 | 152.4 | 157.2 | | 25.4 | 215.9 | | 5 | 5.563 | 13 | 5.69 | 1.75 | 2.38 | 1.88 | 7.44 | 7.31 | 8 | 1.12 | 10.5 | 24.4 | | 141.3 | 330.2 | 144.5 | 44.5 | 60.45 | 47.8 | 189 | 185.7 | | 28.4 | 266.7 | | 6 | 6.625 | 14 | 6.75 | 1.88 | 2.62 | 2 | 8.75 | 8.5 | 12 | 1.12 | 11.5 | 28.7 | | 168.3 | 355.6 | 171.4 | 47.8 | 66.55 | 50.8 | 222.3 | 215.9 | | 28.4 | 292.1 | | 8 | 8.625 | 16.5 | 8.75 | 2.19 | 3 | 2.25 | 10.75 | 10.62 | 12 | 1.25 | 13.75 | 43.4 | | 219.1 | 419.1 | 222.3 | 55.6 | 76.2 | 57.15 | 273.1 | 269.7 | | 31.75 | 349.3 | | 10 | 10.75 | 20 | 10.88 | 2.5 | 3.38 | 2.56 | 13.5 | 12.75 | 16 | 1.38 | 17 | 70.3 | | 273 | 508 | 276.3 | 63.5 | 85.9 | 65 | 342.9 | 323.8 | | 35.1 | 431.8 | | 12 | 12.75 | 22 | 12.94 | 2.62 | 3.62 | 2.75 | 15.75 | 15 | 20 | 1.38 | 19.25 | 84.2 | | 323.8 | 558.8 | 328.7 | 66.55 | 91.9 | 69.85 | 400.1 | 381 | | 35.1 | 489 | | 14 | 14 | 23.75 | 14.19 | 2.75 | 3.69 | 2.88 | 17 | 16.25 | 20 | 1.5 | 20.75 | 98.7 | | 355.6 | 603.3 | 360.4 | 69.85 | 93.7 | 73.15 | 431.8 | 412.7 | | 38.1 | 527.1 | | 16 | 16 | 27 | 16.19 | 3 | 4.19 | 3.06 | 19.5 | 18.5 | 20 | 1.62 | 23.75 | 142 | | 406.4 | 685.8 | 411.2 | 76.2 | 106.4 | 77.7 | 495.3 | 469.9 | | 41.1 | 603.3 | | 18 | 18 | 29.25 | 18.19 | 3.25 | 4.62 | 3.12 | 21.5 | 21 | 20 | 1.75 | 25.75 | 173 | | 457.2 | 743 | 462 | 82.6 | 117.3 | 79.25 | 546.1 | 533.4 | | 44.5 | 654.1 | | 20 | 20 | 32 | 20.19 | 3.5 | 5 | 3.25 | 24 | 23 | 24 | 1.75 | 28.5 | 220 | | 508 | 812.8 | 512.8 | 88.9 | 127 | 82.6 | 609.6 | 584.2 | | 44.5 | 723.9 | | 24 | 24 | 37 | 24.19 | 4 | 5.5 | 3.62 | 28.25 | 27.25 | 24 | 2 | 33 | 312 | | 609.6 | 939.8 | 614.4 | 101.6 | 139.7 | 91.9 | 717.6 | 692.1 | | 50.8 | 838.2 | |

NOTE:

1. Class 600 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option. |

| Production Capacity & Purchase Details | | | 1. | Supply Flange Dimension DN15 - DN2000 (1/2" - 80"), Forged Flange. | 2. | Material Carbon Steel: ASTM A105, A181, A350 LF1, A350LF2, A350LF3, A36, A234 WPB, Q235B, 20#, 20Mn etc. | 3. | Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc. | 4. | Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc. | 5. | Monthly Output: 3000 tons per Month. | 6. | Delivery Terms: CIF, CFR, FOB, EXW. | 7. | Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight etc. | 8. | Minimum Order Quantity: 1Ton or 100Pcs. | 9. | Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service. | 10. | Find More Requirements In Flanges Market. |

|